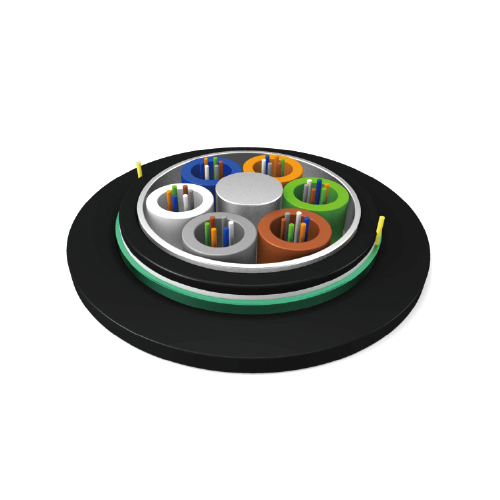

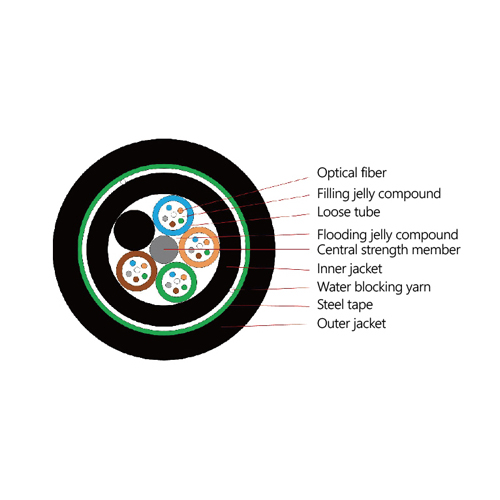

The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic.

The tubes are filled with a water-resistant filling compound. A steel wire,

sometimes sheathed with polyethylene (PE) for cable with high fiber count,

locates in the center of core as a metallic strength member. Tubes (and fillers) are

stranded around the strength member into a compact and circular cable core.

The cable core is filled with the filling compound to protect it from water ingress,

over which a thin PE inner sheath is applied. After the PSP is longitudinally applied

over the inner sheath, the cable is completed with a PE outer sheath.